Ultrasonic inspection of hollow axles and shafts

Key

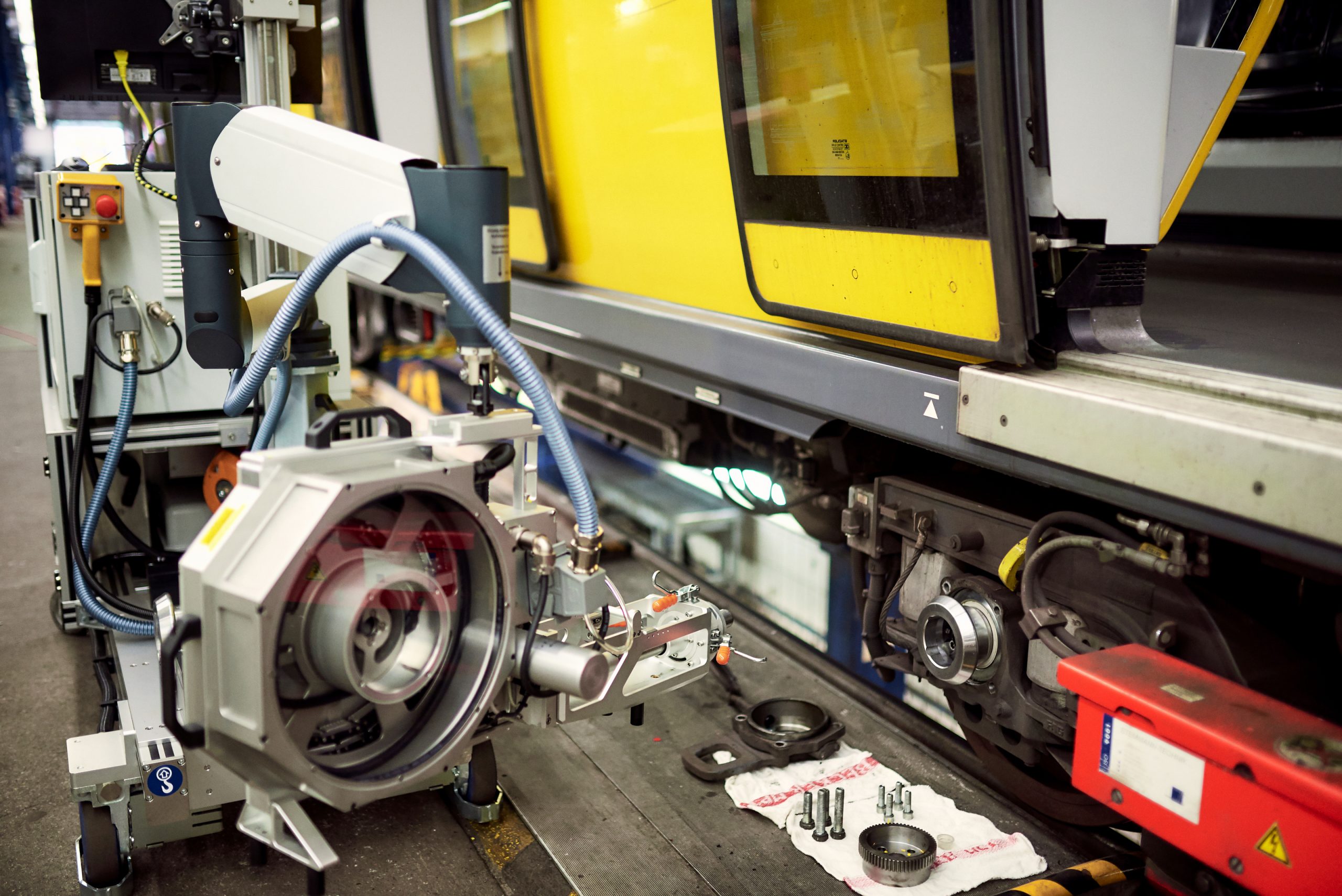

- Interchangeable immersion technike probes in rotating probe system

- Non-contact inspection with oil as couplant

- Diameter range: ≥ 25 mm

- Easy adaption of probe system diameters

- Feed unit with integrated cable and chain storage

- Electric lifting system with remote control for attachning the feed unit

- Fast and ergonomic setup

Features

- Space requirement of only 1 m

- Inspection times per axis: 10 minutes

- System availability: 97% (just 3% downtime for routine maintenance)

- Detection of transverse, longitudinal as well as volume defects

- Certified according to the regulations of German, Swiss, and British railroad operators

Application

Inspection of axles in light maintenance

The axles of trains must be inspected regularly for signs of fatigue caused by dynamic loads and external influences using ultrasound. In light maintenance, this is done with the SHUTTLE system directly on the train from the longitudinal bore of the axle. This enables a reliable evaluation of the axle condition with minimum downtimes. The SHUTTLE system can be optimally adapted to the local conditions of the depot.

Technical data

| Trolley dimensions |

LxWxH in mm: min.: 1060 x 720 x 1210 / max. 1060 x 720 x 2008 |

| Hardware | PC for inspection with industrial screen and keyboard |

| UT electronics with position-dependent amplification | |

| PLC | |

| Software | Convenient inspection software |

| Easy parameterization | |

| Easy documentation of inspection results | |

| Manual and mechanized inspection possible | |

| Special analysis operation | |

| PGC editor for setting up new axes | |

| Optional storage of TD data for offline analysis | |

| Couplant | Integrated oil circuit, oil tank capacity 10L |

| Oil pressure adjustable | |

| 230 V UPS for chang of location without system shutdown (30 min) | |

| Probes | 4,5 MHz probes |

| Probe system for 30 mm bores: four probes (2×37° and 2×0,5°) | |

| Probe system for 53 mm to 90 mm bores: eight probes (2×37°; 2×0,5°; 2×45° and 2×70°) | |

| Adaption of probe system to other sizes possible | |

| Rotation speed max. 90 rpm, feed per revolution 3-5 mm | |

| Trigger distance 1° |

-

Sofware and control

-

Models and optional features

-

Acceptance, commissioning and training

We are your NDT specialist.

Steel | Railway | Aerospace

Any questions?

Actemium Cegelec Mitte GmbH

Actemium NDS

Gutenstetter Straße 14a

90449 Nuremberg

Germany

Tel.: +49 911 9943-0

E-Mail: info.nds@actemium.de