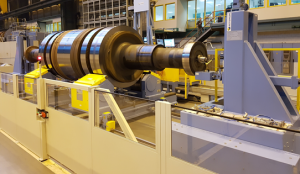

Ultrasonic inspection of shafts and rotors

Inspection task

- Reliably inspects long cylindrical components (e.g. rotors, shafts, shanks) in horizontal position

- Mechanized ultrasonic inspection

- Inspection of cylindrical workpiece surface as well as ends by swiveling inspection system

- System for near surface defects and defects in the workpiece volume

Features

- Workpiece supports adjustable in length and diameter

- Height-adjustable workpiece supports to be able to test shafts with different diameters

- Anti-drift unit to prevent the shaft from drifting away during inspection

- Additional calibration station possible

Technical data

- Pneumatically actuated inspection system (number of probes depending on requirements)

- Phased array or conventional ultrasonic inspection technology

Inspection of rotors and shafts

- Max. diameter: 3000 mm

- Max. length: 20 m

- Max. weight: 350 t

We are your NDT specialist.

Steel | Railway | Aerospace

Application

Ultrasonic testing of turbine rotors for large power plants

The rotors inspected with the TURO-MAN are e.g. further processed as turbines, and used in power plants to generate electricity. Due to the large forces acting there, even small defects can have serious effects on the function of the component.

With the TURO-MAN, turbine rotors can be inspected in various production stages. Defects in the material can thus be detected at a very early stage in the manufacturing process and appropriate steps can be derived from this.

Any questions?

Actemium Cegelec Mitte GmbH

Actemium NDS

Gutenstetter Str. 14a

90449 Nuremberg

Germany

Tel.: +49 911 9943-0

E-Mail: info.nds@actemium.de