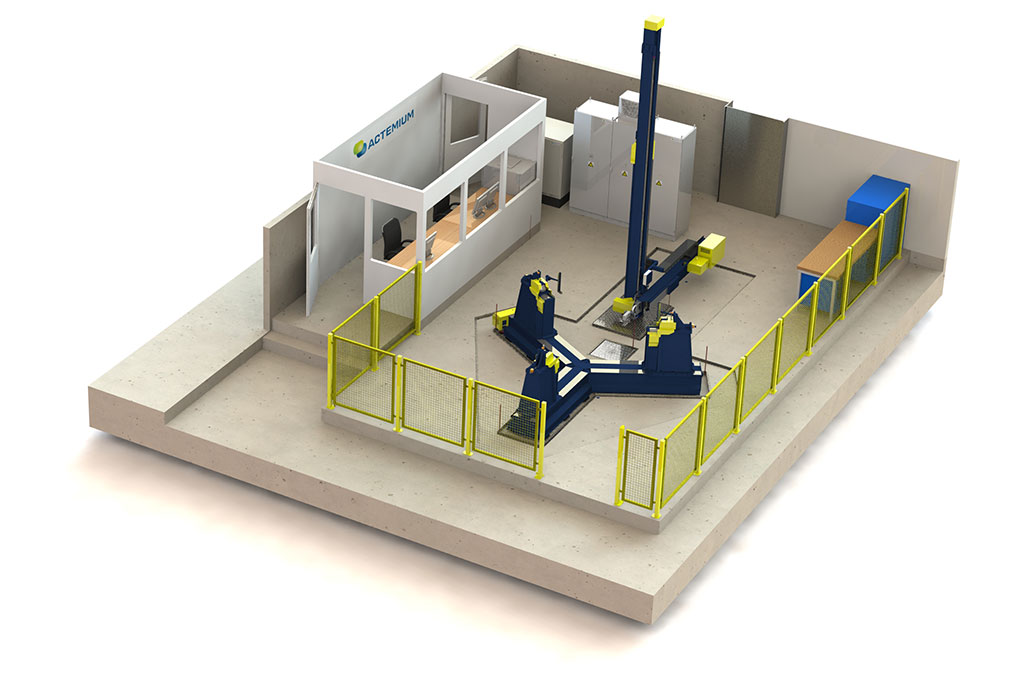

Ultrasonic testing of discs and rings

Inspection task

- Reliably inspects discs, rings and cylindrical components

- Two turning devices with equal load capacity

- Parallel inspection and loading enables increased throughput

- Depending on the configuration, one or more turning devices/roller blocks to reduce set-up times

Features

- Flexible and reliable system for different sized components

- No time-consuming turning of the workpieces necessary

- Swivel axis enables ultrasonic testing of top and bottom side

- Inspection of components on the outer surface (circumference) as well as from the bottom and top face

Technical Data

- Pneumatically actuated inspection system (number of probes depending on requirements)

- Phased array or conventional ultrasonic inspection technology

- Camera system for monitoring the inspection

Inspection of rings and discs

- Max. diameter: 6500 mm

- Max. height: 150 mm to 2500 mm

- Max. weight: 30 t

We are your NDT specialist.

Steel | Railway | Aerospace

Application

Ultrasonic testing of bearing rings and gears for wind turbines

Due to the high requirements of bearings for wind turbines, the rings are inspected with a SIRO-MAN at various stages of production. In the event of a material defect, this makes it possible to derive the appropriate steps at a very early stage in the manufacturing process.

Other rings are further processed into gears after ultrasonic testing with the SIRO-MAN. The inspection prior to further processing of the rings makes it possible, for example, to set the milling contours in later production steps in such a way that the defect is no longer located in the component.

Any questions?

Actemium Cegelec Mitte GmbH

Actemium NDS

Gutenstetter Str. 14

90449 Nuremberg

Germany

Phone: +49 911 9943-0

E-Mail: info.nds@actemium.de