Reliable ultrasonic inspection

Inspection task

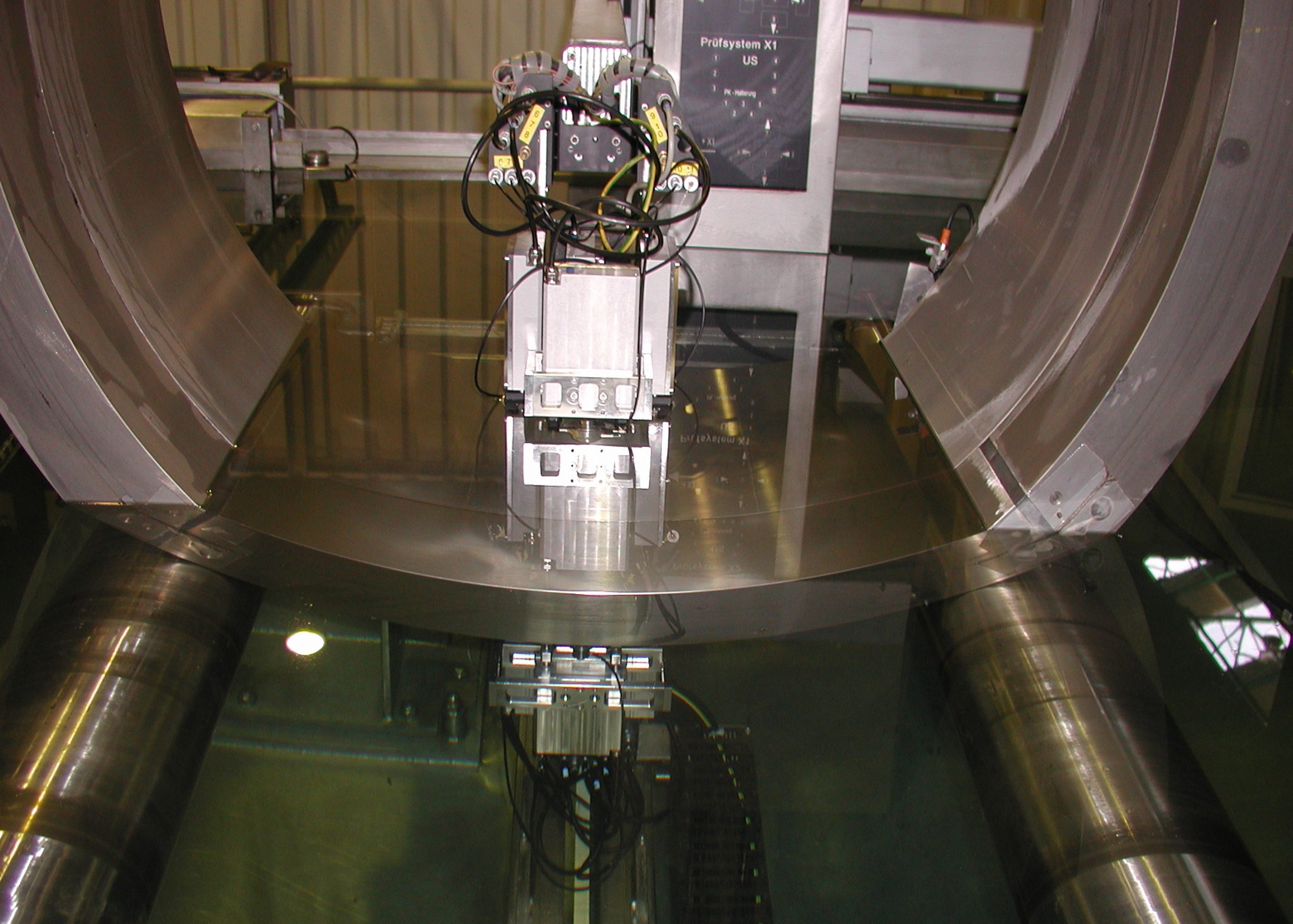

- Inspection of rings in immersion technology

- Adaptable ring support enables the inspection of different ring parameters

- Anti-drift unit prevents the ring from drifting away during inspection

Features

- Reduced space requirement due to vertical ring orientation

- Ultrasonic and eddy current inspection

- Inspection of rings from the inner and outer shell surface

- Reduced set-up times, as ring is only partially immersed in the coupling medium

Technical data

- Adjustable roller blocks for inspection of different ring diameters

- Number of probes according to requirements

- Max. Diameter: 2500 mm

- Max. Thickness: 1500 m

- Max. Weight: 5 t

We are your NDT specialist.

Steel | Railway | Aerospace

Application

Ultrasonic inspection in immersion technique of rings (retaining rings for generators)

In some cases, an inspection with ultrasound as well as with eddy current is required. This was realized with the GERRIE. The rings are inspected in immersion technique or puddle technique. Adjustable roller blocks allow the testing of different ring diameters in vertical orientation.

Any questions?

Actemium Cegelec GmbH

Actemium NDS

Gutenstetter Str. 14a

90449 Nuremberg

Germany

Tel.: +49 911 9943-0

E-Mail: info.nds@actemium.de